Kiwiplan Training by Advantive

Explore the many training options available for Kiwiplan users of all levels.

Drive Lean Manufacturing Results with Kiwiplan Software

Kiwiplan offers a wide range of training opportunities for everyone within your organization including corporate, regional and plant management, office staff, schedulers, and factory personnel. Proper training will prepare your staff to use Kiwiplan tools effectively and help you to gain benefits and achieve the ROI from Kiwiplan products.

Kiwiplan trainers conduct training directly at your location during and throughout the implementation of Kiwiplan software solutions. This valuable on-site training provides employees with classroom style, and one-on-one opportunities to maximize learning retention.

We offer an assortment of advanced training courses at our training facilities. These expert-led courses help participants develop skills and comprehensive product knowledge with a hands-on classroom-style experience with Kiwiplan software products. Participants learn how to best apply and utilize the Kiwiplan software in their jobs. They are challenged and inspired to consider new and better ways to do their job using powerful tools available to them.

Advantive is pleased to develop customized training solutions to meet your specific needs.

Specialized training can include curriculums designed to address Lean Manufacturing initiatives, OEE Improvements, Waste Reduction, and more. Customized training may also be developed for your Management Teams, Customer Service and others.

A selection of online training options is available. Web-based training is flexible, cost-effective and convenient. Online courses allow participants to “attend” classes at their convenience from home or the office. Lessons can be completed in 15 minutes or less. Fit them in when you can and eliminate the need for costly travel and extended time away from the job.

What to Expect

- Honest conversation about your training requirements

- Discover what training programs best fit your team

- Instant access to free, on-demand product training and documentation

Advantive Scheduling Services

Learn more about our unique scheduling solutions built for manufacturers to reduce waste, eliminate downtime, and improve visibility.

Maximize Plant Performance

At Advantive, we have a team of experienced professionals with years of corrugator and production scheduling experience who are here to help you improve visibility and increase production efficiency across your entire manufacturing facility. We are available to schedule your box plant, sheet feeder or manufacturing facility either permanently or temporarily when your schedulers are away. They can schedule your plant remotely from our office location or from your location.

Increase Shop Floor Efficiency and Productivity

Hear what some of our manufacturing customers have to say about their experience with Advantive’s scheduling services.

Kiwiplan: Integrated Packaging ERP & MES Solutions

From sheet and box plants to display and specialty packaging manufacturers, Kiwiplan empowers packaging companies with digital, industry-leading capabilities that help:

- Maximize throughput and daily square footage with enhanced visibility and automated tracking and scheduling.

- Increase efficiency by integrating shipping and production planning.

- Save time and improve value by keeping your entire factory floor connected and up to date.

- Improve product quality, accuracy, and delivery with advanced automation.

New Customers

Existing Customers

Integrated ERP and MES Software for Packaging Manufacturers

Kiwiplan provides a comprehensive, integrated suite of powerful products to meet the specific order management and manufacturing requirements of today’s corrugated, folding carton, plastics, and packaging manufacturers. From the standard single manufacturing facility to complex multi-plant groups, Kiwiplan provides expertise, flexibility, and powerful tools to meet and exceed your system requirements.

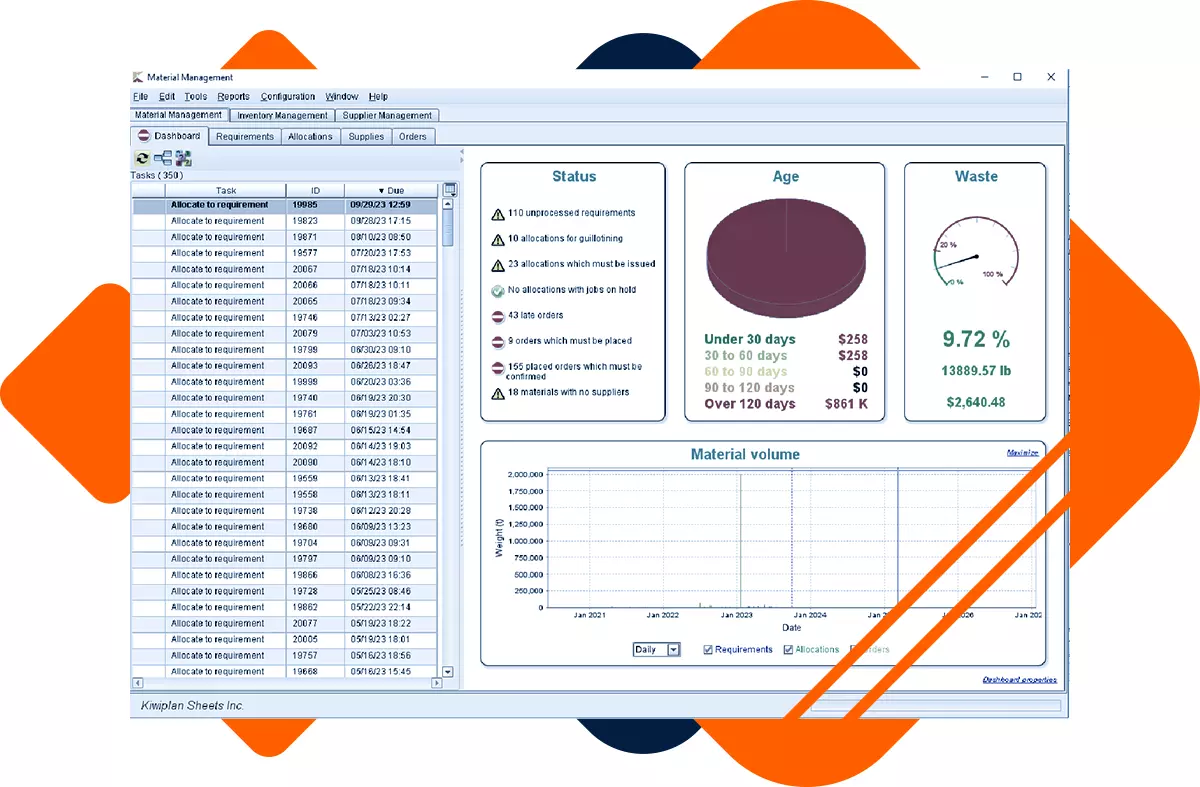

The Kiwiplan MES solution is comprised of a suite of powerful and tightly integrated software modules that offer automated production planning, tooling management, shop floor data collection, dashboard and KPI reporting, quality management, and more. This solution is directly integrated with Kiwiplan Order Management, Inventory and Logistics, and Business Intelligence modules.

- Corrugator Scheduling

- Automated Corrugator Scheduling

- Production Control System

- Quality Management System

- Transmission Links

- Labels

Kiwiplan’s extensive inventory and logistics functionality allow you to manage raw material and roll stock more effectively and reduce material handling costs; Manage and track the location and movement of WIP and FGS inventory; And reduce shipping costs by integrating your truck scheduling and production processes.

- Roll Stock System: Track the ordering, receipt, movement, location, and consumption of raw materials and roll stock. Manage inventory more effectively, maintain accurate inventory and reduce costs. Integrate inventory information directly with the production process to eliminate downtime on the factory floor spent waiting on raw materials.

- Unit Load Tracking: Determine the current and movement of work-in-process and finished goods units. Identify when and where units were moved, when units were shipped and on what truck. Provide WIP and FGS handlers with the information they need to find, move and load units as required.

- Truck Scheduling System: Ship full trucks on time. Adjust loads automatically as needed when the production schedule changes and affects the planned ship time of a load. Ensure the production schedule is adjusted automatically if necessary to accommodate planned ship times.

- Supply Chain Simulator

Kiwiplan provides the tools your sales and customer service staff need to improve communication and deliver the best customer experience.

- Enterprise Sales Processing (ESP): Manage orders, specifications, routing, costing/estimating, pricing, quoting, bills of lading, invoicing, complaints/returns and workflow, and more. Get the accurate data you need to book orders effectively, determine achievable due dates and more.

- Kiwiplan Message Centre (KMC): Improve communication by automatically connecting and sharing information with customers, suppliers, and third-party systems.

Kiwiplan offers accurate data analysis and reporting solutions that let you capitalize on a wealth of information and improve decision-making across your organization.

- Kiwiplan Data Warehouse: Collect and organize data from the Kiwiplan transactional databases from multiple locations as well as other databases (such as financial systems, warehouse management systems, etc.) into a single database optimized for reporting purposes.

- Data Analysis and Reporting Tool (DART): Easy-to-use, cost-effective reporting and analytics solution

Drive Lean Manufacturing Results with Advantive

Kiwiplan ERP and MES software solutions provide manufacturers with the ability to increase production efficiency, improve operational visibility and communication, and respond immediately to changing demand, hot orders, availability of raw materials, and more. As part of the Advantive family, Kiwiplan is one of the largest software providers dedicated to supporting and meeting the particular needs of packaging manufacturers around the globe.

Optimize Your Supply Chain with Kiwiplan Integrations

Kiwiplan has been developing and providing robust, industry-specific software solutions for the corrugated and packaging industry for more than 30 years. Kiwiplan provides powerful tools and functionality to drive improvements in any discrete manufacturing process. Gain the tools you need to collect accurate data, increase visibility, automate scheduling, enhance productivity, and improve quality.

Case Study

Learn how a global paper packaging manufacturer streamlined plant operations, gained real-time visibility and stayed competitive with Kiwiplan software.

What to Expect

- Free 20-minute call with a product expert

- Live demo tailored to your industry requirements

- Discover what products best fit your needs

- No games, gimmicks, or high-pressure sales pitch

Packaging ERP and Manufacturing Software Solutions

- Automate and simplify complex manufacturing processes with Advantive’s corrugated and packaging ERP software.

- Make smart decisions based on real-time data visibility and insights across global supply chains.

- Reduce material handling costs by managing raw material and roll stock more effectively.

Modern Solutions for Packaging Manufacturers

Advantive offers a complete integrated suite of software applications to meet the specific order management and manufacturing requirements of today’s corrugated, folding carton, plastics, and packaging manufacturers.

Simplify Complex Packaging Production Processes

To manage orders more efficiently and compete in a highly competitive market, modern packaging manufacturers need powerful tools and functionality to streamline the production process, capture and analyze real-time data, and drive lean manufacturing and OEE improvements. With better visibility, you can easily identify and improve first pass yield (FPY), reduce waste and downtime, improve capacity and quality, and eliminate manual data entry.

Innovative Packaging ERP and MES Solutions for Packaging Manufacturing

From inventory and logistics management to reporting and business intelligence, our specialized ERP and MES solutions help packagers of all types and complexities improve production efficiency and maximize cost savings. In addition to key functions like order management, costing and pricing, inventory management, and supply chain optimization, core features include:

Automate your costing and pricing process based on customizable rules established by your own company. Easily compare prices of similar items, and modify pricing metrics to see the impact on margin. Price changes are implemented quickly and effortlessly, with access to timely profitability analytics with post-production costing.

Schedule your plant to run on a continual basis using Just-in-Time (JIT) and Theory of Constraints (TOC) lean production philosophies. Our packaging software helps you easily evaluate machine constraints, resource and tooling availability, order backlog and shipping requirements, and optimize efficiency, throughput and on-time delivery. It also allows you to quickly identify bottlenecks in your production process, balance load across similar machines, and make adjustments to the schedule as needed.

Drive your business forward and make informed decisions with access to accurate data across your entire operations. Our packaging solutions provide the functionality you need to eliminate time-consuming, error-prone manual data consolidation and view detailed financial information and precise production data anywhere. Supervisors and managers can monitor machine progress, performance, waste, and downtime remotely from any office location, or anywhere worldwide with secure internet access.

Incorporate quality management directly within your production process. Define quality assurance test requirements and customize tests quickly and easily. Automatically prompt production floor operators to perform tests at the required time and interval, record test results in real-time at workstations on the floor, and eliminate the need for handwritten notes and delayed data entry. Collect test data electronically from testing devices, and alert management or designated staff via text message or email of persistent quality problems.

Case Study

Discover how a family-owned packaging manufacturer modernized their business, expanded their service line, and strengthened their reputation with Advantzware ERP technology.

What to Expect

- Free 20-minute call with a product expert

- Live demo tailored to your industry requirements

- Discover what products best fit your needs

- No games, gimmicks, or high-pressure sales pitch