A bread company which has made public statements of intent to increase nutrition levels has installed WinSPC. The company uses the system to see charts that uncover interrelation between process factors.

A large bread company is using WinSPC real-time statistical process control to alert staff, in advance, of potential bread deficiencies.

The bakery has made a public statement of intent to reduce the amount of sugars and saturated fats baked into their breads. The company also formally stated it will increase the amounts or nutrients they add, such as whole grains.

The company is successfully up and running with the WinSPC solution, collecting data on the shop floor. Temps from thermometers, color readings from Minolta color readers, and certain PLC data, are captured by the system. This data is captured, in part, automatically at timed intervals.

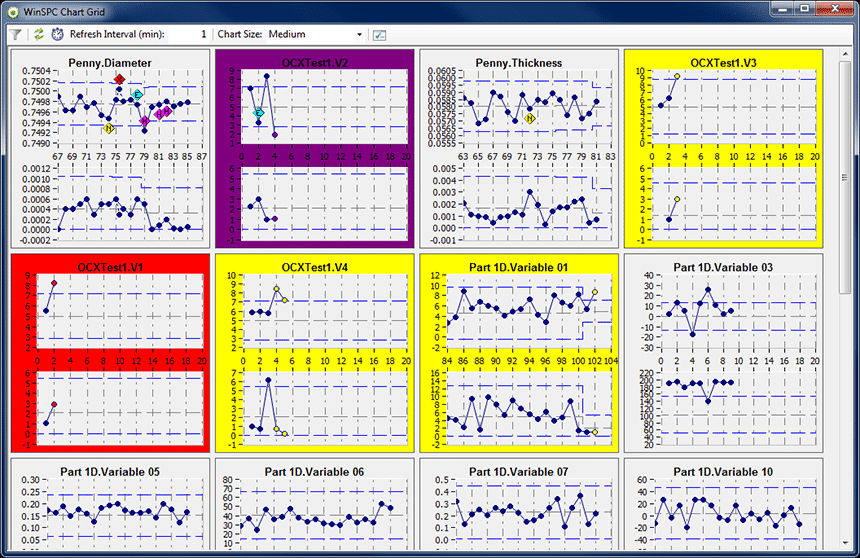

WinSPC dashboards provide high-level insight into production happenings

Together with the KPIs listed above, the bakery captures weight data across 7 bread production lines. This data is tested against Western Electric rules programmed into the WinSPC system.

Data is available for viewing on dashboard displays that offer a visual summary of production health.

About DataNet Quality Systems

DataNet Quality Systems empowers manufacturers to improve products, processes, and profitability through real-time statistical software solutions. The company’s vision is to deliver trusted and capable technology solutions that allow manufacturers to create the highest quality product for the lowest possible cost. DataNet’s flagship product, WinSPC, provides statistical decision-making at the point of production and delivers real-time, actionable information to where it is needed most. With over 2500 customers worldwide and distributors across the globe, DataNet is dedicated to delivering a high level of customer service and support, shop-floor expertise, and training in the areas of Continuous Improvement, Six Sigma, and Lean Manufacturing services.