The capability index dilemma: Cpk, Ppk, or Cpm

Lori, one of our customers, phoned to ask if Cpk is the best statistic to use in a process that slits metal to exacting widths. As a technical support analyst, I too wondered what index would be best suited for her application. Perhaps Cpk, Ppk, Cpm, or some other index offers the best means of reporting the capability of her product or process. Each of these capability indices can be calculated using software such as SQCpack.

Lori’s process capability index, Cpk, has never dipped below 2 and typically averages above 3. Given this high degree of capability, she might consider reducing variation about the target. While the Cpk and Ppk are well accepted and commonly-used indices, they may not provide as much information as Lori needs to continue to improve the process. This is especially true if the target is not the mid-point of specifications.

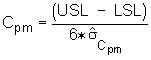

Cpm incorporates the target when calculating the standard deviation. Like the sigma of the individuals formula, compares each observation to a reference value. However, instead of comparing the data to the mean, the data is compared to the target. These differences are squared. Thus any observation that is different from the target observation will increase the standard deviation.

As this difference increases, so does the Cpm. And as this index becomes larger, the Cpm gets smaller. If the difference between the data and the target is small, so too is the sigma. And as this sigma gets smaller, the Cpm index becomes larger. The higher the Cpm index, the better the process, as shown in the diagrams below.

We can use Lori’s raw data to provide an example of how Cpm is calculated:

In a process with both upper and lower specifications, the target is typically the midpoint of these. When such a high degree of capability exists, one may want to ask the customer if the target value is ideal. Lori should check with her customer to determine if he or she wants a small shift toward one of the specifications. Regardless of the target in relation to the specifications, the focus should always be on making the product to target with minimum variation. Cpm is the capability index that accurately depicts this.

Reference: L.J. Chan, S.K. Cheng, and F.A. Spiring, “A New Measure of Process Capability: Cpm,” Journal of Quality Technology, Vol.. 20, No. 3, July, 1989, p. 16.